Engiso TBR Brackets©

TBR Magnetic Bracket System. Semi permanent, non-penetrating, non-destructive, magnetic mechanical interphase bracket system to be integrated between a ferrous steel surface and a product to be installed fast and efficient without having to weld.

Key features

Engiso TBR Brackets© multipurpose neodyme magnet

Semi permanent - non destructive

Semi permanent, non-penetrating, non-destructive magnetic mechanical interphase bracket system.

Fast and efficient

TBR Brackets© are to be integrated between a ferrous steel surface and a product to be installed fast and efficient without having to weld.

Heavy duty solution

Up to 3000 Lbs perpendicular load (1360 kg.) and -40°F (-40°C) to +176°F (+80°C) operation temperature.

Specifications

Semi permanent, non-penetrating, non-destructive, magnetic mechanical interphase bracket system to be integrated between a ferrous steel surface and a product to be installed fast and efficient without having to weld.

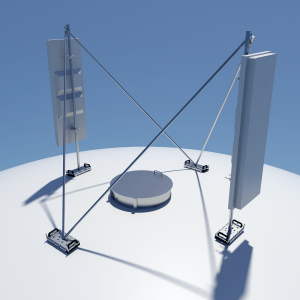

Applicable areas

TBR Brackets© from Engiso can be applied in various business areas. Including wind energy, the oil & gas industry, the telecom sector, defense and marine.

If you would like a free quotation or learn more about how TBR Brackets can optimize your workflow and finances - feel free to contact us.

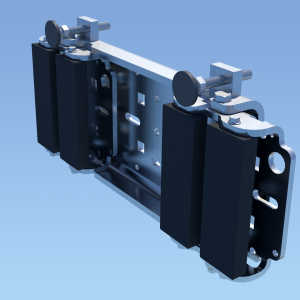

TBR 1500

Heavy Duty Aluminum Bracket with two Engiso V-Mag© 340. Non EX. EPDM coated Engiso N52 V-Mag© 340’s

Size:

L: 8.0” (204 mm)

W: 6.7” (170 mm)

H: 1.8” (46 mm)

MAX Load Capacity:

X - Horizontal: 220 Lbs. (100 kg.)

Y - Vertical: 220 Lbs. (100 kg.)

Z – Perpendicular: 1500 Lbs. (680 kg.)

Mounting Surface: Steel / Ferrous

Thickness (Min.): ¼” (6 mm)

Flat: Yes

Convex - Max: D > 5 feet

Concave - Max: D > 5 feet

Paint thickness - Max: 11 mils (300 μm)

With steel thickness below ¼” (6 mm) the MAX Load Capacity is reduced, please contact ENGISO With paint thickness greater than 11 mils (300 μm) the Max Load Capacity is reduced, please contact Engiso

Install Attributes:

Handles for positioning:

2 ea. Side Flaps

2 ea. M8 connections compatible with Engiso D-Mount Tool (Sold separately).

Tie-Off Tethering Point(s): 2 ea.

Leveling feet: 2 ea.

Hardware:

4 ea. M6 x .8” (20 mm.) - SS

2 ea. M8 x .6” (15 mm.) – SS

1 ea. M12 Levelling Feet

Temperature:

- 40°F (-40°C) to + 176°F (+80°C)

Humidity:

10% to 100% relative humidity according to IEC 60721 3K6

Warnings / Hazards:

Pinch, Crush & Pacemaker on / in

Product, Packaging & Manuals

Logo:

Engiso® Engineered Solutions

V-Mag®

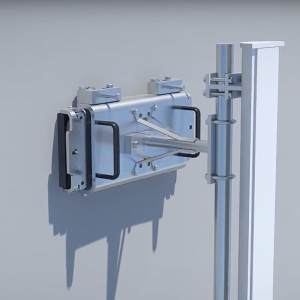

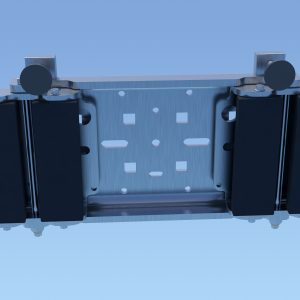

TBR 1500 W

Heavy Duty Aluminum Bracket with two Engiso V-Mag© 340. Non EX. EPDM coated Engiso N52 V-Mag© 340’s

Size:

L: 8.0” (204 mm)

W: 16.2” (410 mm)

H: 3.8” (96 mm)

MAX Load Capacity:

X - Horizontal: 330 Lbs. (150 kg.)

Y - Vertical: 220 Lbs. (100 kg.)

Z – Perpendicular: 1500 Lbs. (680 kg.)

Mounting Surface: Steel / Ferrous

Thickness (Min.): ¼” (6 mm)

Flat: Yes

Convex - Max: D > 7 feet

Concave - Max: D > 7 feet

Paint thickness - Max: 11 mils (300 μm)

With steel thickness below ¼” (6 mm) the MAX Load Capacity is reduced, please contact ENGISO With paint thickness greater than 11 mils (300 μm) the Max Load Capacity is reduced, please contact ENGISO

Install Attributes:

Handles for positioning:

2 ea. Handles included

Tie-Off Tethering Point(s): 2 ea.

Leveling feet: 2 ea.

Hardware:

4 ea. M6 x .8” (20 mm.) - SS

2 ea. M8 x .6” (15 mm.) – SS

2 ea. M12 Levelling Feet

Temperature:

- 40°F (-40°C) to + 176°F (+80°C)

Humidity:

10% to 100% relative humidity according to IEC 60721 3K6

Warnings / Hazards:

Pinch, Crush & Pacemaker on / in

Product, Packaging & Manuals

Logo:

Engiso® Engineered Solutions

V-Mag®

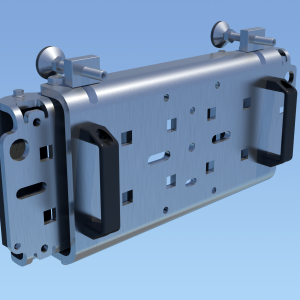

TBR 3000

Heavy Duty Aluminum Bracket with four Engiso V-Mag© 340. Non EX. EPDM coated Engiso N52 V-Mag© 340’s

Size:

L: 10.4” (265 mm)

W: 20.5” (520 mm)

H: 4.2” (106 mm)

MAX Load Capacity:

X - Horizontal: 440 Lbs. (200 kg.)

Y - Vertical: 440 Lbs. (200 kg.)

Z – Perpendicular: 3000 Lbs. (1360 kg.)

Mounting Surface: Steel / Ferrous

Thickness (Min.): ¼” (6 mm)

Flat: Yes

Convex - Max: D > 8 feet

Concave - Max: D > 8 feet

Paint thickness - Max: 11 mils (300 μm)

With steel thickness below ¼” (6 mm) the MAX Load Capacity is reduced, please contact ENGISO With paint thickness greater than 11 mils (300 μm) the Max Load Capacity is reduced, please contact ENGISO

Install Attributes:

Handles for positioning:

2 ea. Handles included

Tie-Off Tethering Point(s): 2 ea.

Leveling feet: 2 ea.

Hardware:

4 ea. M6 x .8” (20 mm.) - SS

2 ea. M8 x .6” (15 mm.) – SS

2 ea. M12 Levelling Feet

Temperature:

- 40°F (-40°C) to + 176°F (+80°C)

Humidity:

10% to 100% relative humidity according to IEC 60721 3K6

Warnings / Hazards:

Pinch, Crush & Pacemaker on / in

Product, Packaging & Manuals

Logo:

Engiso® Engineered Solutions

V-Mag®